ENGINEERING & CONTRACT MANUFACTURING

The ATP engineering team provides a comprehensive set of capabilities from minor design changes to assistance with product development. Our team is involved every step of the way from upfront concepts to final turnkey manufacturing.

By integrating the knowledge of the ATP applications team, we will quickly transition from prototypes into robust, validated manufacturing processes scalable to your production volumes.

Regardless of the simplicity, complexity or the stage of its development, ATP offers all of the services essential to streamline the production of your components. With our in-house capabilities and we can eliminate the risk and delays of dealing with multiple vendors.

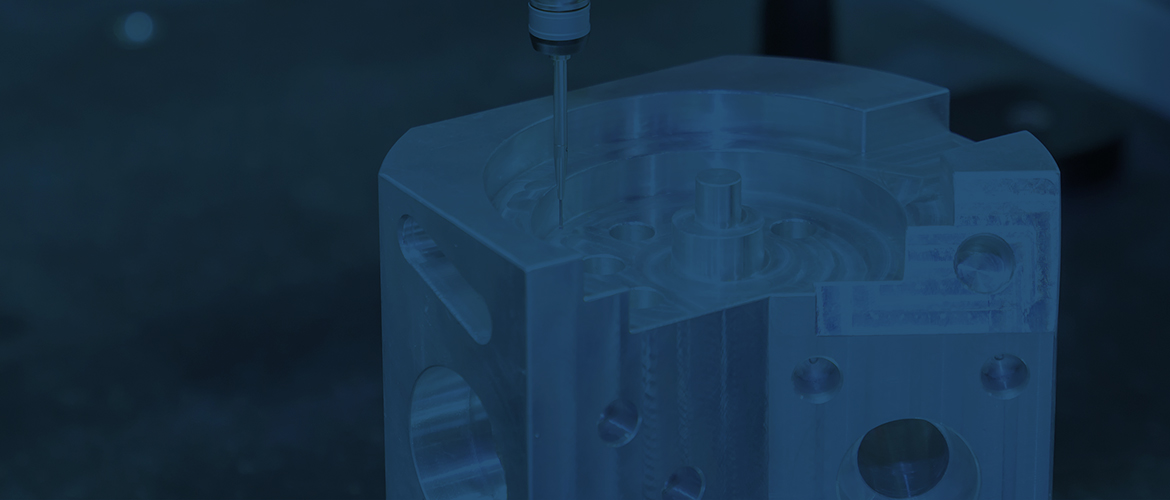

PRECISION MACHINING SERVICES

ATP Industries has been machining components for Aerospace applications since 1928. The company has evolved from producing components on manual machinery to having the most advanced CNC machinery money can buy.

With over 70 CNC lathes and CNC machining centers ATP is ready to take on your most complex, critical application components. From our multi-pallet, 5-axis machining centers to our 9-axis CNC Swiss turning centers we can machine almost any part without the need for secondary operations.

Our PrecisionWorx division in Puerto Rico can handle high volume complex parts for the Aerospace and Medical industries. We have a lean and cost competitive facility set-up to meet the needs of our customers. All of our facilities operate under our ISO/AS9100 certification and are managed under one internal quality system.

ADDITIVE MANUFACTURING SERVICES

Additive Manufacturing is a technology that produces three-dimensional parts layer by layer from a metal based material. The powder material is fused together using a laser to melt and fuse the material. The method relies on a digital data file being transmitted to a machine that then builds the component. The AM systems have enabled the fabrication of usable parts made in the desired material in a single-step process. It is now possible to manufacture almost 100% dense functional designs which can replace castings, forgings or barstock components.

ATP Industries / PrecisionWorx can produce complex shape components from various materials including Inconel, Titanium and Aluminum. We have the ability to machine the parts to final print specifications after the printing process is complete.