ATP Industries is a world class contract manufacturing company that services the Aerospace, Medical, Fluid Control and Firearms sectors. We manufacture a wide range of products from precision machined components to complete turn-key assembled products. With over 70 CNC milling and turning centers, plus 3D Metal Printing/Additive Manufacturing, ATP excels in everything from low volume prototypes to high volume production runs. We can also assist in the engineering process to ensure your product is designed for the highest quality and lowest cost to manufacture.

WHY CHOOSE ATP INDUSTRIES?

Our dynamic facility is set-up to meet your needs on everything from rapid proto-types to high volume production runs. To keep our pricing competitive, we have developed a strong Lean Manufacturing/Continuous Improvement culture, which is evident throughout our facility.

Our dedicated staff has decades of experience in developing manufacturing processes and producing complex components. Our strategy is to continue to invest into new equipment, technology, and highly skilled personnel to stay ahead of our competition.

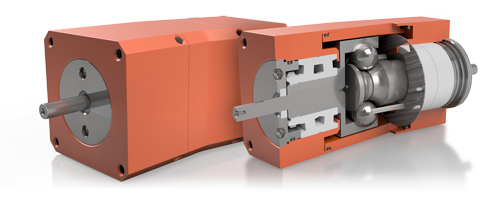

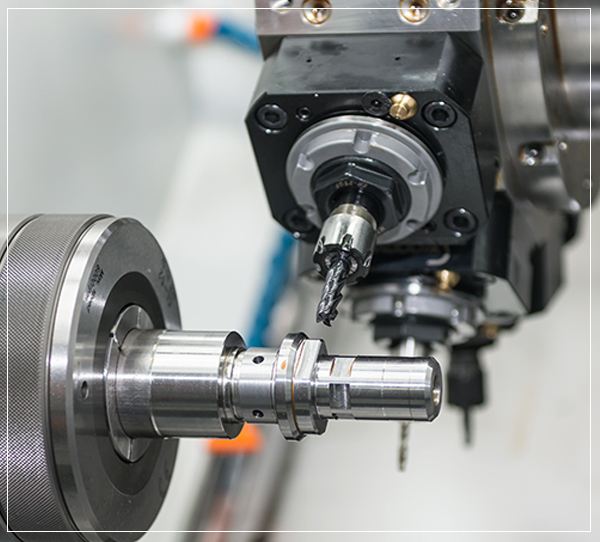

PRECISION MACHINING SERVICES

By having the latest 3&5-axis CNC turning and milling equipment,multi-axis Swiss turning, plus numerous secondary process capabilities, it allows us to manufacture complex part geometries in virtually all materials.

ADDITIVE MANUFACTURING SERVICES

Additive Manufacturing is a technology that produces three-dimensional parts layer by layer from a material, be it polymer or metal based. The method relies on a digital data file being transmitted to a machine that then builds the component. The AM systems have enabled the fabrication of usable parts made in the desired material in a single-step process. It is now possible to manufacture almost 100% dense functional designs.

GROUND-BREAKING AMAZING TECHNOLOGY

We specialize in machining materials high temp alloys such as Inconel, Hastelloy, Waspelloy, titanium as well as carbon steel, brass, aluminum, stainless steel and many types of plastics. We’ve developed a strong supplier base for secondary operations such as plating, heat treating, FPS precision deburring, and broaching.